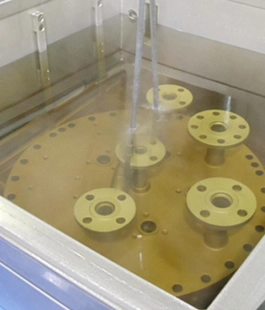

Many of our customers have a specific process or procedure that must be followed with each component. For this reason, Kaytech creates an MPP (Material Process Plan) for repetitive jobs where stringent design specifications are required. This MPP provides illustrated instructions for our operators. The plan also includes a “Quality Assessment” document that travels with the job during the process. Prior to the start of the job, the Material Process Plan is sent to the customer for review and approval.

Inspection - After surface preparation procedures have been completed, every component is inspected by management prior to shipping.

Kaytech strives to keep our soils, forests and streams clean. All of our abrasive media is collected and sent back to the manufacturer to be recycled and reused. Our organization maintains a very small waste stream and we pass those savings on to our customers.

Inspection - Kaytech uses the latest coating inspection software to observe and report our work to our customers.

These inspection reports include:

- Description of scope of work

- Contract requirements

- Industry standards

- Pictures of ongoing work

- Observed Defects

- Environmental Conditions

- Surface Preparation Methods Used

- Coating thickness measurement

- Non-Conforming Items

- Instrument Calibration Information

- Approval by Management

Upon completion of work, these digital records are maintained in a secure database for our customers at no cost.